ATC CNC router is a kind of smart CNC machine with an automatic tool changer spindle kit. It is also called an Automatic Tool Changer, and the common ATC spindle usually carries 6 cutters, 8 cutters, 10 cutters, or 12 cutters. When working with the CNC router, the tool can switch automatically according to the demand of work, and no person is needed in operation, thus having excellent performance at its starting and great torque may exploit the advantage of its high speed, enabling a high-efficiency functioning. It applies the high-power servo motor that possesses all characteristics of low noise, great speed, and precision in position.

Equipped with a unique tool-changing mechanism, you can exchange the required tools at will, and the dedicated tool setting table can accurately compensate for the tool length error. The tool change time only takes a few seconds, which will improve the working efficiency greatly. There are two most common types of ATC CNC machines, which include linear-type automatic tool changers and rotary-type automatic tool changers. The best ATC CNC router machine adopts a rotary 4th axis for 3D cutting and carving.

Features of 2000*4000mm ATC CNC Router with Rotary Automatic Tool Changer Kit

1. Heavy-duty machine body.

2. 9.0KW HQD air cooling spindle.

3. Automatic Tool Changer spindle with tools magazine of 12 cutters.

4. Taiwan LNC controlling system.

5. China large torque 1500W servo motor and drivers.

6. 11KW Fuling inverter.

7. Taiwan HIWIN 30 square rails.

8. Japan Omron limited switch.

9. Strong suction dry vacuum pump 7.5KW.

10. Tool sensor.

11. Auto oil lubrication.

12. 4th rotary axis for 3D carving for option.

Technical Parameters of 2000*4000mm ATC CNC Router with Rotary Automatic Tool Changer Kit

| Model | USM2040A |

| Table size | 2000mmX4000mmX200mm |

| Repositioning resolution | ±0.02mm |

| Max running speed | 50m/min |

| Max cutting speed | 30m/min |

| Tool magazine | Linear Type 12 tools |

| Working voltage | 380V/3 Phase/50HZ or 220V/3 Phase/Single phase/60HZ |

| Spindle | 9.0KW HQD air cooling |

| Spindle speed | 24000r/min |

| Driving system | Leadshine servo motor and drivers 1500W |

| Software | Artcam |

Details of 2040 CNC Router with Linear ATC (Automatic Tool Changer)

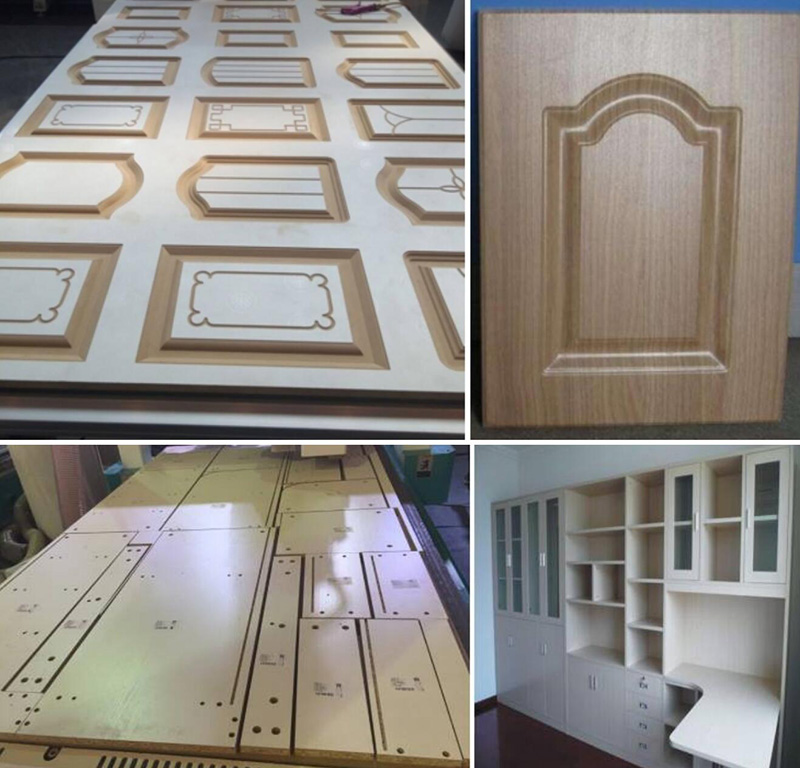

ATC CNC Router Machine Applications

1. Woodworking Industry: Stereo wave board processing, wooden doors, cabinet making, and other furniture production.

2. Advertising Industry: Label making, PVC plate, PCB board (drilling and engraving), double color boards, logo production, acrylic cutting, plastic suction for making advertising dedication, word cutting, sign making, crystal word, LED display screen, doorplate, nameplate, etc.

3. Mold Industry: Wood mold, foam mold, and metal mold, etc.

4. Musical instrument industry: Instrument 3D surface carving, shape cutting

5. Woodcrafts.

6. Exhibition industry: Showcase.

Benefits of Using a ATC CNC Router for Woodworking and Metalworking

A ATC CNC router provides the best efficiency, precision, and versatility for both woodworking and metalworking. Whether a furniture maker, signage manufacturer, or metal fabricator, one can easily find a huge boost in productivity with reduced human effort through the use of a ATC CNC router.

Increased Productivity with Automatic Tool Changes

The ATC system allows the machine to switch between multiple tools automatically during operation. This eliminates the need for manual tool changes, saving time and reducing errors. Complex designs that require various tools can be completed in a single setup.

Precision and Consistency

Equipped with advanced motion systems and high-quality spindles, these routers deliver precise cuts and engravings. This consistency ensures that every piece produced meets exact specifications, reducing material waste and ensuring professional results.

Versatility for Various Materials

A ATC CNC router can handle a range of materials, including hardwood, plywood, aluminum, and softer metals. This versatility makes it suitable for diverse applications such as furniture production, cabinetry, metal signage, and decorative items.

Large Working Area

The worktable provides ample space for large-scale projects, allowing you to process full-size sheets of material without the need for resizing or additional setups. This is particularly useful for projects like doors, panels, and custom metal designs.

Cost-Efficiency in the Long Run

Although the initial investment may seem high, the efficiency, precision, and reduced labor costs make it a cost-effective solution over time. By automating repetitive tasks, it frees up skilled labor for more creative and high-value work.

Projects of ATC CNC Router with Automatic Tool Changer Kit

Hot Tags: 2000*4000mm atc cnc router with automatic tool changer kit for sale, China, manufacturers, suppliers, factory, price, for sale